It needed a strong frame to build upon so off to Canadian Tire I went to brouse and buy. Whatever materials I chose had to be available in small sizes for the scale model and large sizes for the final sculpture. Up and down the aisles I wandered with many items on the shelf inspiring possible solutions. Eventually I settled upon two threaded rods about 85 cm long and two brackets. Each rod would be attached to the wooden base, run from the dancer's foot then up the leg, torso and out the arm. Brackets would tie them together at the dancer's hips and shoulders.

Next I needed some foam to build a lightweight core around the frame and chose Home Depot as the source. Fortunately there were many types and sizes of foam available that people use as home insulation. I loaded my cart with a few hard white sheets, a coil of flexible plastic insulation (that I ended up not using) and a spray can that creates foam to fill cracks. Out on the back deck I sprayed foam around a test wire and was pleasantly surprised at the high potential. Setting the dancer frame on the table, I sprayed foam aound the bottom then gradually worked my way up to create columns for the legs. Round and round I slowly sprayed to form the torso, head and arms. Numberous times the soft foam crumbled under its own weight but I found that occassional pauses to let the foam harden enabled me to build the entire core.

The full size sculpture will be to too large to build with spray foam so will need to have chunks of hard white foam sheets as filler with spray foam around them.

Files and sandpaper proved to be too abrasive to shape the foam but a sharp exacto knife worked wonderfully. Gradually unwanted chunks were removed, revealing the dancer within. It turns out the dancer is female. I didn't know that until now.

Knowing that future layers of wire mesh and Winterstone would make the dancer bulky, I perfomed many iterations of thinning until the foam dancer looked like a grossly thin Nightmare Before Christmas character. Feet and hands were completely removed so that they could be thin and simply made from wire and Winterstone.

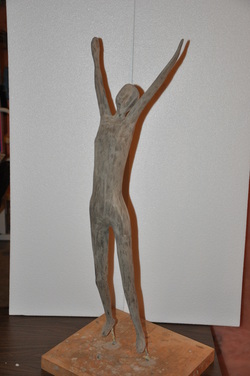

Its difficult to see in this photo, but the foam core is now wrapped in metal mesh and flat pieces of mesh show where the feet and hands will be.

Finally two coats of raw sienna tinted Winterstone were applied, followed by two coats of tinted Winterstone icing. The rough edges were shaped with coarse sandpaper between each coat. Progressively finer grits of sandpaper were used to shape and smooth the surface.

RSS Feed

RSS Feed